Adrian Clarke’s D8 Decorticator

Adrian Clarke’s D8 Decorticator

Please note update (2020) : Due to the fact that we have now up-scaled our growing program, the Clarke D8 method of processing hemp is not a viable option for us. We are currently in the process of installing a brand new full fibre processing facility, which will be installed into the factory at NZYarn Christchurch New Zealand. We will be producing fibre and hurd and on-processing into eco-matting, wool/hemp yarns and more to supply industries. We have left this article on our website for historical value and respect for Adrian Clarke.

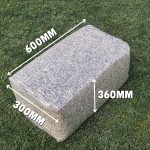

After almost 20 years of development, the technology to separate hemp fiber and cellulose fresh from the field is finally available as the Clarke D8 decorticator. This 2017 harvest we have successfully processed fresh hemp stalks into hemp fiber and hurd, products which can be utilized by a wide variety industries. This innovation is a world first, and a massive step in increasing efficiency for hemp farmers.

Hemp fiber is traditionally produced using a hammer mill. This is a multi-million dollar facility that separates the fiber by forcefully “hammering” the hemp stalks. This obviously weakens the fiber. Another downside to the hammer mill is the fact that the hemp is required to ret in the field for around 6 months before it can be processed, as the fresh fiber contains too much sticky resin for the hammer mill process to work. This makes the production of hemp fiber a very costly process, not only due to the cost of building the factory, but also the loss of land for half of a year.

The Clarke D8 decorticator, named after the late inventor Adrian Clarke, addresses both of these large financial obstacles. The machine costs a fraction of the price of a hammer mill, and farmers can use their land immediately after harvest. The Clarke D8 decorticator was developed from scratch, when Adrian Clarke realised that it must be possible to separate these two universally useful elements fresh from the field. Through many iterations and prototypes, this was achieved.

The 2017 Clarke D8 didn’t just work in principle, it successfully generated an abundance of fiber from the crop. The machine has been built strong, after being intentionally pushed to the limits during development. In fact, a team of engineers were tasked with breaking the D8, so that weak points could be identified. These points of weakness were then redesigned, rebuilt, and retested until they stood up to the abuse that the world’s strongest fiber will throw at it.

The fiber created by the Clarke D8 is as smooth and strong as physically possible. This is because the fiber has incurred no damage as part of the process, whether it be mechanical (such as in the hammer mill) or biological (such as in the process of retting). We believe that our machine is now capable of producing the strongest plant fiber on Earth.

From The Hemp Farm Team

Hi is this D8 available in South Africa

Many thanks

Peter

Hello,

Can you please me from where may I import Adrian Clarke’s D8 decorticator to India. I need it for small scale processing of Himalayan Hemp.

I would be really grateful to you for your reply.

Regards,

Sunil Devrari

Goa, India