Hemp Green Building & Construction

Strong, Insulating, Fire-Resistant & Sustainable

Hemp is a fantastic building material from an ecological, constructional, and financial perspective.

Hemp buildings are constructed with a frame and then the walls are infilled with hemp hurd, which is the woody inner layer of the hemp stalk. Hemp hurd is extracted using a hemp processing line, incorporating what is commonly known as a decorticator. This machine separates the hemp fibre from the woody core of the hemp stalks. Our partner NZ Natural Fibres is currently installing a processing line ready for production starting 2021. Did you know that hemp is the world’s strongest plant fibre?

The environmental impact of new buildings is significant. Hemp growing actually helps to clean up the environment, so the production of hemp building materials is environmentally-friendly. Hemp also won’t release harmful toxins, which means a safe and healthy living environment for the occupants.

Carbon Footprint. Does Hemp absorb carbon?

Hemp is the most efficient annual plant for carbon sequestering. Regardless of the end use of biomass it´s roots binds few tons of carbon in the soil. It´s an ideal carbon sink.

One hectare of industrial hemp can absorb 22 tonnes of CO2 per hectare. It is possible to grow to 2 crops per year so absorption is doubled. Hemp’s rapid growth (grows to 4 metres in 100 days) makes it one of the fastest CO2-to-biomass conversion tools available, more efficient than agro-forestry.

Does 1 acre of hemp produce more oxygen than 25 acres of trees?

Only 1 acre of hemp is said to produce more oxygen than 25 acres of current forest. Wood pellets are very common, however hemp pellets for stoves and boilers are a much better solution.

Is Growing hemp environmentally friendly?

Industrial hemp is a very robust, competitive plant that will out-compete weeds. Bio-products made of hemp can produce environmentally friendly products that are easily recycled in compost or in landfills. Most hemp-derived products are non-toxic, biodegradable and renewable. Discover the environmental benefits of hemp.

What is Hempcrete?

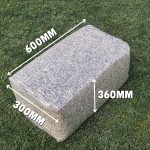

Hempcrete is a bio-composite made of the inner woody core of the hemp plant mixed with a lime-based binder. The Shiv (hemp core) has a high silica content, allowing it to bind well with lime. This property is unique to hemp among all-natural fibers. The result is a lightweight cementitious insulating material weighing about a seventh of the weight of concrete.

What are the benefits of hempcrete?

- Non-structural thermal insulation

- No off-gassing, non-toxic, low VOC, free of allergens

- Made from natural renewable raw materials

- Replaces layers of petroleum-based products

- Biodegradable

- Sequesters CO2

- Self-regulates temperature and humidity

- Durable, Breathable material

- Fireproof

- Pest resistant & Mold Resistant

- Excellent acoustic performance

- Factory prefabricated with little waste

- Lightweight, Easy Installation. Self-Build friendly

How long will Hempcrete last?

With these bricks, the need for a wooden frame is practically zero, and since they eventually turn to petrified rock they will last for hundreds of years.

Hempcrete Recipe Mix

Wall-insulation hempcrete at a ratio of 1 part chopped hemp hurd by weight, with 1.5 parts of the binder by weight. After translating these weights to volume measurements, it approximates 4 buckets of hemp hurd going into the mixer with 1 bucket of binder (1/2 lime, 1/2 metakaolin).

Contact HBA NZ with any Hemp Building Enquiries

Contact HBA NZ if you have any queries regarding building with hemp in New Zealand.

Kevin McCloud on hempcrete

Hempcrete House Wanaka New Zealand

Hawea Grove EP12, SE01 - A House of Hemp

Locky and Joel from Erkhart Construction take us through the process of building with hempcrete. We also talk to Dave from Hemp NZ to hear about the coming Christchurch processing plant.

Hawea Grove EP14, SE01 - Interior Finishings

In this instalment the Hawea Grove team look at the benefits of lime plaster, low VOC paint from Dulux, and the internal door handles supplied by Windsor Hardware.

Prefab hempcrete-insulated walls

The Smart Prefab Building System

The Dun Agro Hemp Group has designed prefab panels, a house can be built in such a way that it is windproof and watertight within one week. The innovative design ensures thermal bridges are avoided. The panels can be pre-wired and come with cut-outs for frames as well, which is a very handy feature. This will save you a lot of time.

Lime hemp panels can also be easily utilised in a traditional construction method. For example, they can be used for the insulation of the roof, inner walls and floors.

History insight

By 1937, the United States was already importing most of its hempseed and fiber from countries with cheaper labor, and the timber and paper industries in the United States were completely invested in the Kraft process for making newsprint.

In 1937, commercial wild bird feed was primarily made from hempseed, and hempseed was also pressed for oil used in the manufacture of paints, varnishes, and other coatings.

Industrial-scale hemp production mostly continued in the USSR (Union of Soviet Socialist Republics) and China until modern petroleum products slowly began to replace products previously made from hempseed oil and hemp fiber. At least in the days of the USSR, hempseed oil for human consumption was called “black oil,” because of its high chlorophyll content, which was especially used by those who were too poor to afford butter.

The Marihuana Tax Act of 1937 had very little impact on the use of marijuana as a narcotic in the United States, if for no other reason than the Act did not penalize the possession or use of hemp, cannabis, or marijuana. It did, though, penalize persons dealing commercially in these products. Thus, the Act effectively brought all industrial hemp production in the United States to a grinding halt by the next year.

Hemp Key To Zero-carbon Houses

Hemp, a plant from the cannabis family, could be used to build carbon-neutral homes of the future to help combat climate change and boost the rural economy, say researchers at the University of Bath.

A consortium, led by the BRE Centre for Innovative Construction Materials based at the University, has embarked on a unique housing project to develop the use of hemp-lime construction materials in the UK.

Hemp-lime is a lightweight composite building material made of fibres from the fast growing plant, bound together using a lime-based adhesive. The hemp plant stores carbon during its growth and this, combined with the low carbon footprint of lime and its very efficient insulating properties, gives the material a ‘better than zero carbon’ footprint.

Professor Pete Walker, Director of the BRE Centre for Innovative Construction Materials, explained: “We will be looking at the feasibility of using hemp-lime in place of traditional materials, so that they can be used widely in the building industry.

“We will be measuring the properties of lime-hemp materials, such as their strength and durability, as well as the energy efficiency of buildings made of these materials.

“Using renewable crops to make building materials makes real sense – it only takes an area the size of a rugby pitch four months to grow enough hemp to build a typical three bedroom house.

“Growing crops such as hemp can also provide economic and social benefits to rural economies through new agricultural markets for farmers and associated industries.”

The three year project, worth almost £750,000, will collect vital scientific and engineering data about this new material so that it can be more widely used in the UK for building homes.

The project brings together a team of nine partners, comprising BRE Ltd, Feilden Clegg Bradley Studio architects, Hanson Cement, Hemcore, Lhoist UK, Lime Technology, National Non-Food Crops Centre, University of Bath and Wates Living Space. As part of the project the University of Bath received a research grant of £391,000 from the Renewable Materials LINK programme run by the Department for Environment, Food & Rural Affairs (DEFRA).

The Balehaus on campus.

Low carbon hemp house put to the test

Used to make paper, clothing and car body panels, hemp could also be used to build environmentally-friendly homes of the future say researchers at the University of Bath.

A consortium, led by the BRE Centre for Innovative Construction Materials based at the University, has constructed a small building on the Claverton campus out of hemp-lime to test its properties as a building material.

Called the “HemPod”, this one-storey building has highly insulating walls made from the chopped woody core, or shiv, of the industrial hemp plant mixed with a specially developed lime-based binder.

The hemp shiv traps air in the walls, and the hemp itself is porous, making the walls incredibly well insulated. The lime-based binder sticks together and protects the hemp and makes the building material highly fire resistant.

The industrial hemp plant takes in carbon dioxide as it grows, and the lime render absorbs even more of the climate change gas, effectively giving the building an extremely low carbon footprint.

Dr Mike Lawrence, Research Officer from the University’s Department of Architecture & Civil Engineering, explained: “Whilst there are already some houses in the UK built using hemp and lime, the HemPod will be the first hemp-lime building to be constructed purely for scientific testing.

“We will be closely monitoring the house for 18 months using temperature and humidity sensors buried in the walls, measuring how quickly heat and water vapour travels through them.

“The walls are breathable and act as a sort of passive air-conditioning system, meaning that the internal humidity is kept constant and the quality of the air within the house is very good. The walls also have a ‘virtual thermal mass’ because of the remarkable pore structure of hemp shiv combined with the properties of the lime binder, which means the building is much more thermally efficient and the temperature inside the house stays fairly constant.”

Professor Pete Walker, Director of the BRE Centre for Innovative Construction Materials, added: “The aim of the project is to provide some robust data to persuade the mainstream building industry to use this building material more widely.

Environmentally-friendly building materials are often more expensive than traditional materials, but the Renewable House project funded by the Department of Energy and Climate Change (DECC) and the National Non-Food Crops Centre (NNFCC) demonstrated a cost of around £75,000 (excluding foundations) to build a three-bedroom Code 4 house from hemp-lime making it competitive with conventional bricks and mortar.

The project is sponsored by the Department for Environment, Food & Rural Affairs (Defra) under the Renewable Materials LINK Programme, and brings together a team of nine partners comprising: University of Bath, BRE Ltd, Feilden Clegg Bradley Studios, Hanson UK, Hemp Technology, Lhoist Group, Lime Technology, the NNFCC and Wates Living Space. The high performance windows were kindly supplied by Janex.

References

- https://hemp-copenhagen.com/images/Hemp-cph-Carbon-sink.pdf

- http://www.hemptrade.ca/eguide/background/hemps-environmental-impact

- https://hemp-copenhagen.com/images/Hemp-cph-Carbon-sink.pdf

- https://www.sciencedaily.com/releases/2009/04/090408074401.htm

- https://www.bath.ac.uk/search?query=hemp&collection=website

- https://www.bath.ac.uk/case-studies/bath-researchers-develop-houses-with-zero-carbon-footprint/

- https://www.bath.ac.uk/announcements/low-carbon-hemp-house-put-to-the-test/